Used mineral oils, oily waste water, oil contaminated soil and sludge, other oil contaminated wastes, dielectric liquids, used car batteries and accumulators, contaminated packaging materials, acids and organic chemicals, chlorinated and non-chlorinated solvents, substances containing asbestos, putrescible organic wastes, inorganic slag, ashes, moulding sand and enamel sludge, wooden waste, and organic wastes.

POPs sources and adverse POPs impacts on human health and the environment. The problem is getting worse because of the high poverty level in the country. People have to use solid waste including plastics for heating. Solid waste incineration for local needs results in emission of toxic substances including dioxins. In addition there are hundreds of informal or illegal landfills. Many of them became sources of POPs emissions and other toxic substances because of waste burning.

A realistic evaluation of the presence of PCBs, made by the Ministry, is around 50 tonnes of PCB waste (from transformers and big condensers) and 10 tonnes of contaminated oils with PCB concentrations over 50 ppm (from transformers).

The Group has proven track record in dealing with organic and non-organic sludges, oily wastes, plating acids, arsenic, cyanide, printed circuit board acids and currently processes more than 200,000 tons of such toxic liquid waste. The group has the ability to attend spills, uplift spilt material, remove contaminated soils and ground materials and render the area safe and sustainable after t he cleanup.

Each of the RCR STAG plants will be equipped with specialist vacuum lifting trucks specialized in lifting liquid wastes. These vehicles will be employed to visit each of the dumpsites where liquids will be uplifted from the ponds or areas where they are in evidence in the first instance.

The uplifted material is transported to the liquid toxic waste treatment facility that is co-located at each of the four RCR STAG plants. Any drums of liquids will be carefully uplifted and transported to the liquid waste treatment facility and stored in a bunded area pending treatment.

The method of treatment of liquid wastes will be through the analysis of the material at the on-site laboratories and using the neutralization method of acids and alkalis and the filtrate medium of calcium carbonate to lock in chemicals into Dolomite material that can be safely landfilled in a sanitary landfill.

The plant is also able to offer customers a full “on-site” service to assist with the management of their wastes. This service includes waste analysis, list preparation, packaging and container labelling. This expertise would be put in place to ensure customers fulfil their environmental and legislative responsibilities.

The implementation of the European Landfill Directive in 2002 prohibits the disposal of liquid waste at landfill sites, bringing UK legislation into line with that of mainland Europe. This directive will have a huge impact on the management of hazardous liquid wastes in the UK, and in particular on those waste streams previously considered unsuitable for either biological or chemical treatment. Such wastes are usually characterised by a high COD (chemical oxygen demand) often combined with other complicating factors such as acidity or heavy metal content.

The RCR plant offers a treatment process for high COD waste, which provides waste producers with a viable alternative to disposal at landfill. This process comprises primary chemical treatment followed by the secondary biological treatment of the balanced effluent. Plating wastes; Acid waste; Alkali wastes; Inorganic chemical waste; Reactive organic waste; Organic solvents; Putrescible/organic waste; Textile; Oil; Containers; Immobilized waste; Organic chemicals; Miscellaneous waste.

This process has provided an alternative disposal route to a large number of companies with difficult organic and inorganic wastes. These companies, who were previously reliant upon landfill or incineration as the only cost effective method of disposal; have opted for the long-term environmental security that only the ‘treatment route’ can offer. The plant treat chemicals and substances by using the following methods:

- Acid-base neutralization

- Oxidizer reduction

- Reactive deactivation

- Inorganic and Organic material detoxification

- Metal recovery

Incineration could be used but the environmental impact of releasing huge volumes of toxins and diburfurans into the atmosphere may not be acceptable. Similarly, it is recognized from the brief description provided that some of the material is volatile and explosive and combustion may not be the safest form of disposal.

A small number of specialist vacuum loader trucks will be attached to the proposed plant to handle heavy sludges to powders and other solid materials that may be spilled or difficult to pick up at waste generator’s premises. The DISAB vacuum loader is designed to provide an efficient and cost effective handling solution. One particular feature of this equipment is the potential it provides for working in inaccessible areas. RCR staff are fully trained to operate in confined spaces with breathing apparatus. Where the material to be moved is in an inaccessible location, our technology provides the solution. The power generated by the equipment means that a vehicle does not even need to be close to the material being moved. The powerful suction and adaptive hose allows us to reach the most inaccessible areas.

- Removal of compacted sludges from storage tanks and pits

- Removal of sewage sludges

- De-sludging of culverts and ditches

- Removal of drilling residues

- Movement of aggregates and soils

- Clearance of powder blockages in industrial processes and storage silos

- Clearance of spillages such as concrete dust

The plant incorporates a computerised control system that provides instant technical and operational information for each individual waste stream and tracks its progress through the treatment plant. This system is unique within the UK and provides customers with the further assurance that their environmental responsibilities are discharged with the utmost professionalism.

Oil, oily water and mineral oil based liquid wastes can be separated and cleaned and the resulting product could be used for lubrication purposes in engineering works or could be further treated to be a fuel for trucks or the process plant that would be fitted with dual fuel steam raising boilers.

Insecticides and herbicides, paints, polymers and spirit-based cleaners can all be treated and disposed of in an environmentally compliant manner.

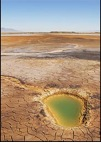

There is evidence that some liquid wastes have already been spilled from containers or been discharged from tankers or trucks into landfill or dumpsites where they have collected in natural hollows. This material as described will be vacuum lifted into trucks for treatment at the main STAG plant. Once all surface liquid has been removed the ground will be excavated and the seepage will be traced so that this or any contaminated sand and substrate can also be excavated.

The excavated material will be transported to the treatment facility where it will be subjected to steam to separate the chemical liquids from the sand. The cleaned sand will be transported back to the dumpsite for top-dressing the areas. The chemicals removed from the sand will be in solution or emulsion with the steam condensate and this will be separated using membrane bioreactor treatment to produce concentrated chemicals that will then be neutralised in the liquid toxic waste treatment plant.

The chemicals once neutralised will be “locked” into Dolomite and this can be safely landfilled in a sanitary landfill specially designed and constructed for this purpose. The landfilled materials will not produce leachate, nor will they be able to produce any Greenhouse gasses. The landfill will be completely inert and non-bioreactive.

It is probable that if a particular dumpsite that has been used for liquid waste disposal is not located where groundwater is vulnerable, and if the excavation necessary to extract contaminated soils is substantial then the resulting excavation may provide the best and most practical venue for the construction of a sanitary and controlled landfill,

A double-skin geomembrane lined landfill could be constructed with leachate treatment and this material is laid on 30cm of clean smooth sand, once the double membrane is laid and welded it is covered with another layer of 30 cm of sand in to which is laid the leachate collection pipes. It is then ready to receive inert neutralised dolomite for indefinite disposal.

A constant vacuum will be applied within the leachate collection pipes to draw off any liquids that may be generated. All of this liquid will be transported back to the liquid toxic waste treatment facility for treatment and further neutralsiation.